Tension wrenches and turning tools are terms often used interchangeably in locksmithing. Both are designed to apply torque to a lock’s plug, holding pins in place during the picking process. However, their designs and placement in the keyway can vary, impacting their effectiveness based on the lock type.

Key Takeaways:

- Purpose: Both tools stabilize the lock’s pins to allow opening.

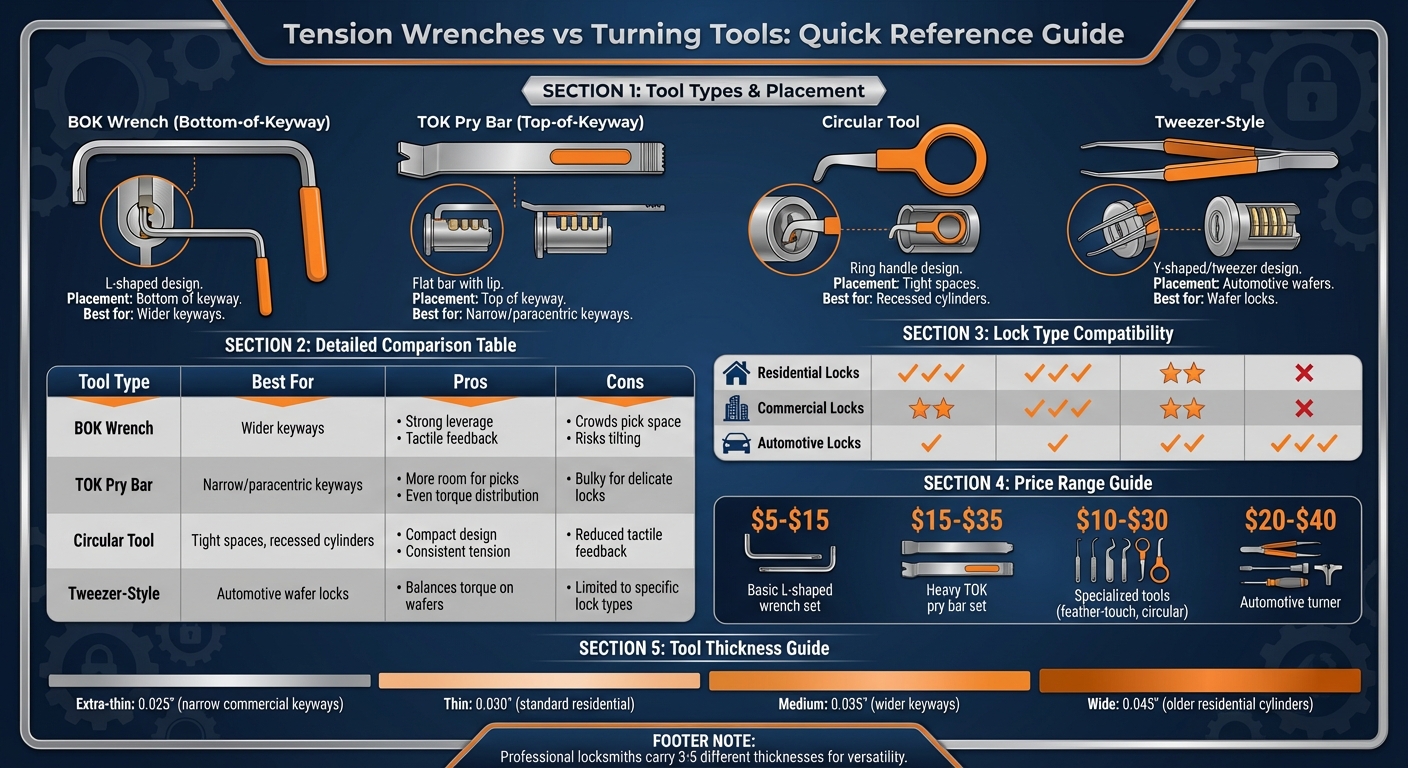

- Types: Common designs include Bottom-of-Keyway (BOK) and Top-of-Keyway (TOK) tools, along with specialized versions like circular, spring-loaded, or tweezer-style tools.

- Differences: BOK tools are better for wider keyways but can crowd the pick, while TOK tools offer more room and even torque distribution.

- Challenges: Using the wrong tool can lead to poor control or damage to the lock.

Quick Comparison:

| Tool | Best For | Pros | Cons |

|---|---|---|---|

| BOK Wrench | Wider keyways | Strong leverage, tactile feedback | Can crowd pick space, risks tilting |

| TOK Pry Bar | Narrow or paracentric keyways | Leaves space for picks, even torque | Bulky for delicate locks |

| Circular Tool | Tight spaces, recessed cylinders | Compact, consistent tension | Reduced tactile feedback |

| Tweezer-Style | Automotive wafer locks | Balances torque on wafers | Limited to specific lock types |

Locksmiths rely on these tools for non-destructive lock picking, ensuring precision and efficiency. The right tool choice depends on the lock type, keyway size, and required torque control.

Locksmith Tension Wrench and Turning Tool Comparison Guide

What Are Tension Wrenches?

Definition and Purpose

A tension wrench is a small, L-shaped or flat metal tool used to apply controlled torque to a lock’s plug during the picking process. Its main job is to hold the pins at the shear line, allowing the lock to be opened. Locksmiths often consider tension wrenches even more important than picks because applying the wrong amount of pressure can prevent the pins from setting correctly. Once all the pins align at the shear line, the same tool is used to turn the plug and unlock the mechanism. Now, let’s look at how different designs address various keyway profiles.

Common Designs

Tension wrenches, typically made from spring steel, come in several styles to suit different locks. One common type is the L-shaped Bottom-of-Keyway (BOK) wrench, which fits along the lower edge of the keyway – where the bottom of a standard key would usually rest. These are widely used with U.S. pin tumbler cylinders, such as those found in residential locks from brands like Kwikset, Weiser, and Schlage.

Another popular option is the Top-of-Keyway (TOK) tension tool, often called a pry bar or heavy bar. These flat tools rest along the upper edge of the keyway, near the pin stacks. By positioning the tool at the top, more space is left for the pick to maneuver, which is particularly helpful in narrow or paracentric keyways often found in high-security locks. Additionally, placing the tool closer to the plug’s center helps distribute torque more evenly, reducing unwanted tilting and ensuring smoother pin binding.

Other designs cater to specific needs. Feather-touch wrenches include a small spring to maintain light, constant torque, helping avoid over-tensioning. Twisted tension tools, with their slightly twisted shafts, act like torsion springs, absorbing sudden pressure changes and providing smoother feedback. There are also double-ended wrenches with different blade widths, long-handled tools for extra leverage, and circular or tweezer-style wrenches designed for wafer and automotive locks. Each variation is tailored to improve efficiency and control during the lock-picking process.

Advantages and Limitations

Tension wrenches are valued for their simplicity, affordability, and ability to provide precise control over plug rotation. These tools are essential for non-destructive access to residential, commercial, and automotive locks. Their compact size allows locksmiths to carry a variety of wrenches in a small kit, making them versatile for different lock types.

"Proper tension control is the key to lock picking, and having the correct tools makes all the difference."

However, tension wrenches do have their challenges. For example, in narrow or heavily warded keyways, a standard L-shaped BOK wrench might take up too much space, limiting the pick’s movement and making it harder to reach rear pins. Similarly, when working in tight spaces, such as near door frames or vehicle bodywork, longer handles can become impractical. Locksmiths address these issues by switching to TOK pry bars, thinner or offset blades, or circular and custom-ground wrenches designed to minimize obstruction while still delivering effective torque.

What Are Turning Tools?

Definition and Use Cases

Turning tools are a cornerstone of a locksmith’s toolkit, offering precision and adaptability for various lock-picking scenarios. These tools are designed to apply controlled torque to a lock’s plug, enabling the pins or wafers to bind and allowing the plug to turn once everything is properly aligned. Essentially, the term "turning tool" reflects its critical role in the lock-picking process. This category includes basic tension wrenches as well as specialized designs created for specific lock types and situations.

In practical locksmith work across the U.S., turning tools are indispensable. They’re used for everything from residential pin tumbler deadbolts to commercial door locks, automotive wafer locks, and recessed doorknob cylinders. For instance, a locksmith handling a house lockout in Pittsburgh might rely on a top-of-keyway pry bar for a narrow deadbolt. Later, they might switch to a wafer-style turning tool to unlock the car door of a domestic sedan.

Specialized Designs

Turning tools go beyond the standard L-shaped tension wrenches, offering advanced designs to tackle unique challenges. Twisted blades, for example, are engineered to absorb pressure fluctuations, preventing over-tensioning in more delicate locks. Tools with stepped or shouldered ends provide varying thicknesses at the tip, making it easier to work with different keyway sizes without jamming the plug.

For added leverage and control, long-handle turning tools are ideal. They’re especially useful for stiff commercial cylinders or scenarios requiring extra stability, as the handle can rest against a surface for support. Circular or round tools with integrated springs are perfect for tight spaces, like those near doorframes or recessed cylinders, as they maintain consistent torque while the locksmith focuses on manipulating the pins. Automotive locks often call for specialized designs, such as Y-shaped or tweezer-style tools, which are particularly effective for wafer locks in vehicle doors. Each of these designs is crafted to meet specific needs, directly impacting how well the tool performs.

Strengths and Drawbacks

Turning tools are incredibly versatile, offering a range of thicknesses and profiles to handle a variety of locks commonly found in the U.S. Top-of-keyway pry bars and circular tools are especially helpful in tight spaces, as they leave more room around the keyway for maneuvering picks. Twisted and spring-assisted tools provide precise torque control, reducing the risk of jamming pins. Additionally, centralized top-of-keyway tools apply torque closer to the plug’s axis, making stubborn cylinders easier to manage.

However, these tools aren’t without challenges, especially for beginners. The sheer variety – bottom-of-keyway, top-of-keyway, twisted, stepped, circular, and more – can feel overwhelming at first. Using the wrong tool thickness might lead to insertion issues or slippage, which can be frustrating and may even leave minor marks on the keyway. High-quality turning tool sets can also be pricey, ranging from $10 to $40+ depending on the materials and number of tools included . And while these tools offer subtle advantages, it takes practice to master their use. Understanding these nuances helps locksmiths pick the right tool for the job, whether they’re working on residential, commercial, or automotive locks.

Comparing Tension Wrenches and Turning Tools

Terminology and Design

Tension wrenches and turning tools both serve the purpose of applying controlled torque to a lock’s plug, but the term "turning tool" is often preferred for its emphasis on specialized designs. Some professionals argue that "turning tool" better reflects the action of applying torque rather than literal tension.

The classic tension wrench is L-shaped, with a short blade that fits into the keyway and a longer handle for leverage. Over time, more advanced designs have emerged, such as TOK pry bars and spring-loaded feather-touch wrenches, which allow for greater precision. Other specialized tools include circular designs for tight spaces and tweezers-style auto turners, particularly useful for wafer locks. These variations play a key role in how the tools are positioned and how effectively they function across different lock types.

Placement and Functionality

Bottom-of-keyway (BOK) tools are placed on the side of the keyway opposite the pins – typically the bottom in U.S. locks. These tools act as a fulcrum for leverage and provide strong tactile feedback. However, their bulk can sometimes crowd the pick, leading to slippage or even tilting the plug.

Top-of-keyway (TOK) tools, on the other hand, rest closer to the pin side, near the plug’s central axis. This placement allows for even torque and leaves more room for picks to maneuver. TOK pry bars are particularly effective in narrow keyways and in areas with limited space, such as near doorframes. While BOK tools excel in larger keyways where extra leverage is beneficial, TOK tools generally provide smoother feedback and better control for precise work.

Here’s a quick breakdown of these design differences and their practical advantages:

Comparison Tables

| Shape/Design | Common Name | Compatible Lock Types |

|---|---|---|

| L-shaped flat bar | Tension wrench (BOK/TOK) | Standard pin tumbler deadbolts, residential cylinders |

| Pry bar (straight with lip) | TOK turning tool | Narrow keyways, U.S. residential locks, tight spaces |

| Circular/ring handle | Circular tension tool | Recessed cylinders, low-profile locks, tight clearances |

| Tweezers-style | Auto/wafer turner | Automotive locks, wafer tumbler cylinders |

| Tool Type | Pros | Cons |

|---|---|---|

| Basic L-shaped wrench | Versatile, strong leverage, affordable ($5–$15 per set) | May slip in narrow keyways, can crowd pick space |

| Heavy TOK pry bar | High torque, frees up keyway, even rotational force | Bulky for delicate cylinders, risk of damage if misused |

| Specialized (feather-touch, circular) | Precision control, constant tension, compact | Reduced tactile feedback, higher cost ($10–$30), learning curve |

This detailed comparison highlights the importance of selecting the right tool for the job, ensuring locksmiths can handle a wide variety of locks with efficiency and precision.

How Locksmiths Use These Tools

Residential and Commercial Locks

When dealing with common U.S. residential locks like Schlage and Kwikset deadbolts or knob locks, locksmiths often start with top-of-keyway (TOK) tools for pin-tumbler locks that have tight or paracentric keyways. Placing the tool at the top of the keyway keeps the lower portion clear for the pick. Many locksmiths prefer a rigid, pry-bar style TOK wrench positioned at the 12 o’clock mark, as it offers reliable control with minimal flexibility.

For locks where the keyway has more clearance at the bottom or when the top ledge is too shallow to hold a TOK tool securely, bottom-of-keyway (BOK) tools are the go-to option. Choosing the right tool thickness and blade width is critical. A tool that’s too thick won’t fit, while one that’s too thin may slip.

For narrow or heavily warded commercial keyways, like those found in restricted or interchangeable core cylinders, locksmiths often rely on extra-thin TOK prybars to save space while securely engaging the ledge. On the other hand, wider or older residential cylinders with more generous keyways benefit from medium or wide BOK wrenches, which offer better stability and reduce issues like chatter or unexpected torque spikes. A well-equipped professional kit typically includes 3–5 different thicknesses for both TOK and BOK tools. Some tools are even double-ended, featuring varied blade widths to handle a range of U.S. residential and storefront locks without requiring on-the-spot modifications.

When working on mortise cylinders, locksmiths favor firm TOK prybars. The larger plug diameter and deeper face of these locks allow for a secure grip while still leaving room for picking. For interchangeable core systems, where the keyway is particularly tight, locksmiths use extra-thin TOK or narrow BOK tools to avoid obstructing the control shear line or causing pin binding. These locks also require lighter, more controlled torque to avoid damaging expensive hardware.

Automotive and Specialized Locks

Locksmiths adapt their techniques for automotive and specialized locks, which differ significantly from residential and commercial ones. Automotive, cabinet, and wafer locks often require unique tools because their keyways and plug faces aren’t designed like standard pin-tumbler cylinders. For example, tweezer-style tension tools apply torque to opposing wafers simultaneously, which is especially helpful in wafer locks where balanced pressure across a broad, shallow keyway is essential.

Inner-groove turners and other specialty tools are designed for automotive keyways, engaging internal grooves where standard L-shaped wrenches might slip or spin. The torque applied in these cases must be light and steady to avoid binding or bending the delicate wafers. Automotive locks often feature shallow wafers and small, rounded keyway ledges, making conventional TOK or BOK tools impractical. Instead, locksmiths rely on deep-seating specialty tools to securely access locks, even in awkward positions like car doors.

Technique Considerations

Success in lock picking hinges on precise technique, especially when working with different lock types. Locksmiths carefully examine the keyway, noting its size, warding, and wear, to select the best tool for the job. For worn or dirty locks, a slightly wider BOK wrench can provide a better grip despite debris. Alternatively, twisted or spring-style tensioners help absorb minor shocks and prevent accidental torque spikes.

For locks with tight tolerances or high-security features, locksmiths switch to thinner, stiffer TOK tools. These tools preserve space in the keyway while still delivering accurate torque. If a tool causes the plug to bind or restricts pick movement, an experienced locksmith will quickly swap it out for another style or thickness rather than risk damaging the lock. For example, a stubborn deadbolt might require switching from a thin TOK prybar to a medium BOK tool for smoother rotation. Similarly, a commercial mortise cylinder that partially turns before seizing might need a rigid TOK prybar to reduce flex and improve tactile feedback, paired with lighter torque to allow the finely pinned drivers to move freely.

Full-service mobile locksmiths – like Sherlock’s Locksmith in Pittsburgh – carry compact but extensive kits in their service vehicles. These kits typically include multiple TOK and BOK tools in various thicknesses, automotive tweezers, circular tension tools for tight spaces, and spring-style or twisted wrenches. Locksmiths are trained to quickly identify the right tool for each situation, which not only speeds up the job but also minimizes the risk of damaging hardware. This is especially critical during emergency lockout calls, where rapid, non-destructive entry is a priority. By using high-quality tools and emphasizing light torque and strong tactile feedback, these locksmiths deliver consistent results no matter the lock or technician on the job.

sbb-itb-643e28e

Building Your Locksmith Tool Kit

Essential Components for Your Toolkit

When it comes to assembling a locksmith toolkit in the U.S., versatility is key. Your kit should include TOK (Top of Keyway) and BOK (Bottom of Keyway) tension wrenches in various thicknesses, typically ranging from 0.025 to 0.045 inches, to handle the diverse keyways found in American locks. These tools are fundamental for efficient lock picking, so having multiple sizes ensures you’re prepared for both narrow and wide keyways.

Additionally, make sure to include specialty turners like circular, feather-touch, and tweezer-style tools. These are indispensable for residential, commercial, and automotive locks, saving you from having to improvise or make adjustments on the spot. A well-rounded toolkit ensures you’re ready for any situation, whether it’s a simple residential rekey or a complex automotive lockout.

Why Quality Tools Matter

Investing in high-quality tools isn’t just about durability – it’s about performance. Precision tension wrenches provide better tactile feedback, helping locksmiths feel pin binds and apply the exact amount of torque needed. Tools that fit snugly in the keyway minimize slippage and prevent scratching, which means faster, more confident work. On the other hand, cheap tools can bend, break, or slip at critical moments, leading to inefficiency and even potential damage to the lock cylinder.

While quality tools may cost more upfront, they quickly pay for themselves. For example, a reliable TOK prybar set costs around $15–$35, and a specialty automotive turner ranges from $20–$40. These tools not only speed up your work but also reduce callbacks, making them a smart investment for any locksmith.

Real-World Example: Sherlock’s Locksmith

Take Sherlock’s Locksmith in Pittsburgh, for instance. Their 24/7 mobile teams are equipped with comprehensive toolkits designed for residential, commercial, and automotive locks. These kits include a variety of TOK and BOK tension wrenches, along with specialty tools like circular turners and automotive tweezer-style picks. This allows them to handle everything from rekeying homes and installing commercial security systems to resolving emergency auto lockouts.

As Sherlock’s Locksmith explains:

"Our seasoned locksmiths come prepared with cutting-edge tools and technology, enabling locksmith to rekey house, craft duplicate keys, and promptly address any emergency lockout situation. We prioritize delivering swift, dependable, and secure service to each of our valued clients."

Their emphasis on using the latest tools and techniques not only minimizes potential damage during emergencies but also ensures consistent, effective results across all types of jobs. A well-equipped toolkit doesn’t just improve efficiency – it highlights the importance of having the right tool for every unique lock.

(500) EVERYTHING About Tension Tools!

Conclusion

Tension wrenches and turning tools are two names for the same essential tool used in lock picking. While the terminology differs – some locksmiths and lock-sport enthusiasts prefer "turning tool" for its focus on the torque applied to the lock’s plug – the purpose remains the same. This tool is indispensable for non-destructive lock picking, as it holds the pins at the shear line during the process.

That said, the design of these tools can make a significant difference, depending on the lock type. For instance, circular and spring-loaded tools perform well in tight spaces where standard L-shaped wrenches might not fit. Similarly, specialized automotive tools are crafted to handle wafer locks that require tensioning from both sides.

Selecting the correct tool – whether it’s a TOK, BOK, or a uniquely designed option – is crucial for both efficiency and success. A tool that’s too thick might block the keyway, while one that’s too thin could slip and fail to maintain steady torque. Poor tool selection can lead to binding issues or even damage. High-quality tools, properly sized for the task, provide better tactile feedback, helping you feel when pins bind and when they set correctly. Professional locksmiths rely on a diverse toolkit to handle a variety of keyway specifications, ensuring effective results for residential, commercial, and automotive locks. This careful attention to tool selection is a cornerstone of efficient and secure locksmithing.

FAQs

What’s the difference between Bottom-of-Keyway and Top-of-Keyway tools?

When it comes to lock-picking tools, their placement within the keyway can make all the difference. Bottom-of-Keyway tools sit at the lower part of the keyway, while Top-of-Keyway tools are positioned at the upper section. This placement directly influences how these tools interact with the lock’s pins during operation.

Bottom-of-Keyway tools are often preferred when the lower part of the keyway offers more space, allowing for better control in specific situations. Meanwhile, Top-of-Keyway tools excel in locks where the upper section provides a steadier grip for applying tension. Choosing between these tools largely depends on the lock’s design and the technique being employed.

What’s the difference between a tension wrench and a turning tool?

A tension wrench is a key tool in lock picking. Its job is to apply torque to the lock’s plug, creating just enough tension to allow the pins inside the lock to be adjusted. This steady pressure is what makes the entire picking process possible.

A turning tool, by contrast, is primarily used to rotate the lock cylinder or plug itself. These tools come in handy for tasks like repairing locks or unlocking them when the focus is on turning the mechanism instead of manipulating the internal pins.

To sum it up, tension wrenches are indispensable for picking locks, while turning tools are more suited for rotating or fixing lock mechanisms.

Why is choosing the right tool important for successful lock picking?

Choosing the right tool is crucial for successful lock picking. It ensures precision, minimizes the risk of damaging the lock, and increases the likelihood of unlocking it effectively. Tools like tension wrenches and turning tools serve different purposes, and selecting the appropriate one depends on the specific design and security features of the lock.

By using tools that align with the lock’s requirements, you can make the process more efficient while preserving the lock’s condition. This is particularly important to avoid unnecessary repairs or replacements, which can be both time-consuming and expensive.